Nanofiltration Pilot Testing and Process Optimization

MBC has extensive experience in optimizing nanofiltration (NF) facilities in South Florida through on-site testing in both pilot-scale and full-scale operation. Based on our success in assisting two large NF facilities completely eliminate sulfuric acid and antiscalant from their treatment processes (resulting in millions of dollars in annual operating cost savings and safer working environments at those plants), as well as comparative testing of other Biscayne Aquifer raw water supplies at several other South Florida NF facilities, MBC has elected to invest in construction of our own mobile NF pilot unit to assist other South Florida utilities with similar objectives. The unit utilizes three full-size (8-inch diameter, seven-element) pressure vessels in a 2:1 array, which provides an ideal pilot-scale representation of any two-stage NF unit that has a proportional array (the most common configuration in South Florida NF plants). We have found that a pilot unit that uses full-size pressure vessels provide a representation of full-scale units that is superior to pilot units that utilize 4-inch pressure vessels or 6-element vessels.

MBC’s pilot unit is ready for operation and can be mobilized to any NF facility in South Florida for site-specific testing for optimization of your facility.

Chemical Pretreatment Optimization, Elimination of Acid and Antiscalant

In 2004, the City of Boca Raton commissioned their 40 million gallon per day (mgd) NF plant. This plant was groundbreaking in more ways than one. In addition to being the largest NF plant in the world at the time of commissioning, it was the first large plant in Florida to successfully operate with no chemical pretreatment, resulting not only in substantial ongoing operating cost savings, but also a safer working environment for plant operators and lower liability exposure for the City. This was achieved through extensive NF pilot testing by the design team (CDM Smith Inc. including project manager Frank Brinson, now Principal Engineer of MBC). For sixteen years (until April 2020), the Boca Raton plant was the only large plant to successfully operate with no chemical pretreatment (at a total savings to the City of over $30 million in chemical costs to date).

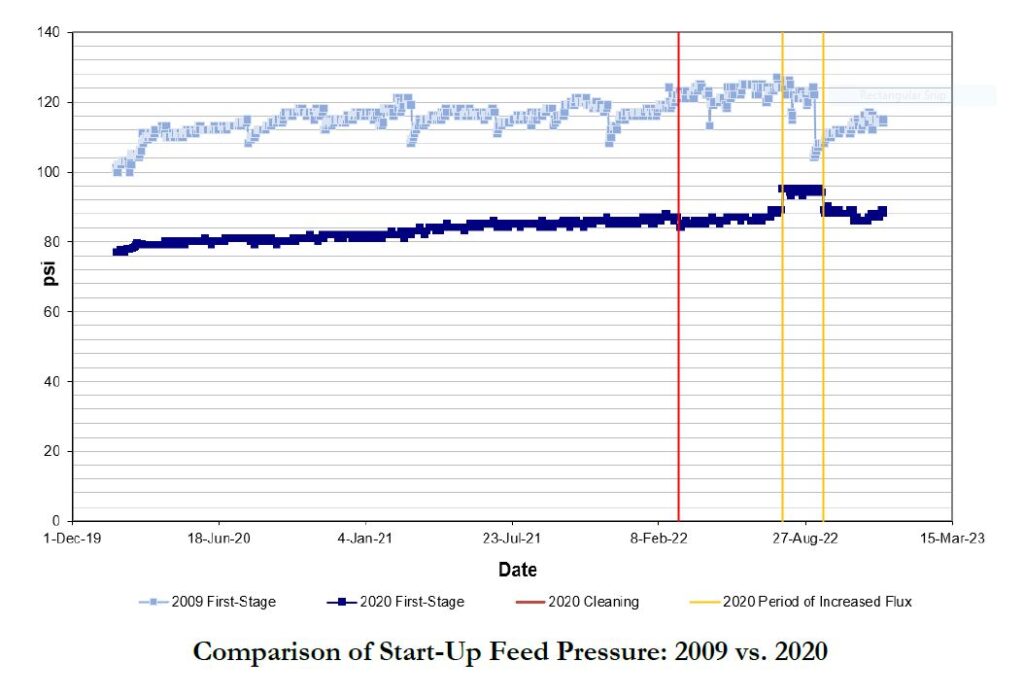

In 2016, MBC began assisting the City of Pompano Beach with design, permitting, and construction of a permanent, on-line pilot test unit for their 10 mgd NF plant. As part of a routine membrane element change-out, MBC assisted the City with a four-year pilot testing program with a dual objectives. The first objective was to pre-qualify membrane element selections from the leading NF element manufacturers. The second objective was to develop an operating approach that allowed the complete elimination of acid and antiscalant pretreatment. The operational parameters of the testing without chemical pretreatment were based on the original pilot testing performed during design of the Boca Raton facility, and historical full-scale operations at Boca Raton. Ultimately, the testing at Pompano Beach was successful, and the plant was started up without chemical pretreatment with the new membrane elements in April 2020. As of August 2023, the Pompano Beach NF plant has been operating for over three years without chemical pretreatment, with their first normal membrane cleaning performed in February. In fact, the first three years of operation of their new membranes, without chemical pretreatment, has been substantially more stable than their last set of membranes.

Through our experience in pilot testing at Pompano Beach and 15-years of continuing NF process optimization consulting at Boca Raton, MBC has learned a great deal about the raw water characteristics and NF process operating conditions that might allow an NF plant in South Florida to operate without chemical pretreatment. The raw water quality characteristics of the surficial Biscayne Aquifer are unique to South Florida. We believe that some of the same constituents that normally contribute to organic fouling of NF membranes can also play a role in “stabilizing” membrane performance in the absence of pretreatment chemicals under certain operating conditions, effectively acting as natural antiscalants.

We believe that stable NF process operations that have been demonstrated at Boca Raton and Pompano Beach may be translatable to other NF facilities in South Florida that use Biscayne Aquifer raw water supplies with similar quality characteristics.

To assist South Florida NF facilities in optimizing their treatment processes, we have developed an approach that maximizes the likelihood of achieving stable, chemical-free NF operation that can be applied to existing operating NF facilities. In the design of new facilities, it is possible to incorporate additional features and operating parameters that can further enhance the opportunity to achieve stable, cost-effective operation without chemical pretreatment. These features can be most effectively developed and tested through design-phase pilot testing.

Please contact our office for additional information on our pilot testing and NF process optimization consulting services.

Special Thanks to Bill Suratt 1940 – 2023